As the world increasingly turns toward electrification and energy storage technologies, batteries have become a cornerstone of modern innovation. From electric vehicles and consumer electronics to renewable energy systems, batteries are essential in delivering power where it is needed most. However, as battery technology advances, one of the most critical challenges that arises is thermal management. Batteries generate heat during both charge and discharge cycles, and if this heat is not effectively controlled, it can lead to performance loss, safety risks, and reduced lifespan. One of the most effective tools used to address this challenge is a Battery Thermal Interface Material, commonly referred to as BTIM. This specialized material plays a crucial role in transferring heat away from battery cells and into the cooling system, maintaining optimal temperatures and enhancing overall efficiency and safety.

Understanding Battery Thermal Interface Materials

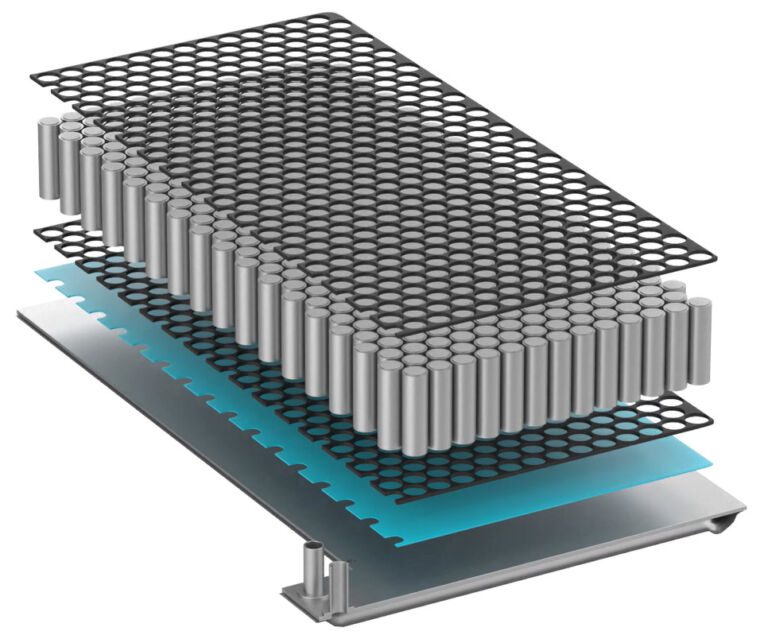

Battery Thermal Interface Materials are substances placed between a battery cell and a cooling surface such as a cold plate or a heat sink. Their purpose is to bridge the microscopic air gaps that naturally exist between surfaces, which otherwise would act as insulators and trap heat. By filling these voids, BTIMs enhance the transfer of heat from the battery to the cooling solution, helping to maintain a consistent and safe temperature during operation.

Unlike general thermal interface materials used in traditional electronics, BTIMs are specifically engineered to meet the thermal, mechanical, and chemical demands of battery environments. Batteries are unique because they are subject to swelling, vibration, and continuous thermal cycling. Therefore, the materials used in these systems must be flexible, durable, and thermally efficient under various conditions.

Why Battery Thermal Management Is Critical

Effective thermal management in batteries is essential for several reasons. First and foremost is safety. Batteries, especially lithium-ion cells, are sensitive to high temperatures. If a battery becomes too hot, it can enter a state of thermal runaway, a chain reaction that can result in fire or explosion. Preventing this condition requires consistent removal of heat from each cell in the battery pack.

Another critical factor is performance. Batteries operate most efficiently within a specific temperature range. If they are too cold, chemical reactions inside the cells slow down, reducing power output. If they are too hot, the internal resistance of the cells increases, which also affects performance. A BTIM helps maintain the optimal operating temperature, which is key for delivering reliable and efficient power.

Longevity is also affected by temperature. High operating temperatures accelerate the degradation of battery materials. This means fewer charge cycles, decreased capacity over time, and ultimately a shorter lifespan. Using a high-quality BTIM to improve heat transfer can significantly extend the life of the battery by keeping it within its ideal thermal range.

Types of Battery Thermal Interface Materials

There are several types of BTIMs, each designed to address specific needs within battery thermal management systems. The most commonly used materials include thermal gap fillers, thermal pads, phase change materials, and thermally conductive adhesives.

Thermal gap fillers are soft, conformable materials that can be dispensed or molded into place. They are highly effective at filling uneven gaps and can accommodate battery cell expansion and contraction due to swelling. These are often used in applications where precise thermal performance and mechanical flexibility are needed.

Thermal pads are pre-formed solid materials that are easy to apply and offer consistent thickness and performance. These are ideal for battery packs where uniform application and repeatable results are important.

Phase change materials become semi-liquid at a specific temperature, allowing them to flow and fill gaps when the battery is in use, and then solidify again as it cools down. These materials offer excellent thermal conductivity and can adapt to changing conditions during the battery’s operation.

Thermally conductive adhesives are used when mechanical bonding is required along with thermal transfer. They can securely attach cells to cooling plates while also conducting heat away. These are useful in space-constrained or vibration-prone environments where mechanical fasteners cannot be used.

Key Properties to Consider in BTIM Selection

Selecting the right BTIM involves considering several performance factors. Thermal conductivity is one of the most important. A higher thermal conductivity means that the material can transfer more heat from the battery to the cooling system, which is essential in high-power applications such as electric vehicles.

Compressibility and conformability are also important, especially when dealing with cells that may swell or when surfaces are not perfectly flat. The material must maintain good contact over time without degrading, even under pressure and repeated thermal cycling.

Electrical insulation is another key consideration. In many battery systems, electrical isolation between components is necessary for safety. Some BTIMs offer both thermal conductivity and electrical insulation, making them ideal for sensitive applications.

Chemical stability and aging resistance ensure that the material will perform well over the life of the battery, resisting degradation due to heat, moisture, and exposure to chemicals that may be present in the battery environment.

Applications in Electric Vehicles and Energy Storage Systems

The use of BTIMs is especially critical in electric vehicles, where battery packs operate at high power levels and are often packed tightly to save space. These systems must be cooled efficiently to ensure safety, range, and battery longevity. A properly selected and applied BTIM helps to remove heat quickly from the battery cells and transfer it to the vehicle’s cooling system.

In stationary energy storage systems, such as those used for renewable energy integration or grid support, thermal management is also essential. These systems may operate in a wide range of environmental conditions and require consistent performance over long durations. BTIMs contribute to the stability and reliability of these systems by keeping battery temperatures in check.

Consumer electronics such as smartphones, laptops, and power tools also benefit from battery thermal interface material. Although these devices do not operate at the same power levels as electric vehicles, they still require effective heat management to maintain performance and ensure user safety.

Importance of Proper Installation and Maintenance

Proper application of a BTIM is critical to its effectiveness. Poor installation can lead to air gaps, uneven thermal contact, and reduced performance. For instance, applying too little material may result in insufficient coverage, while using too much can lead to excess squeeze-out and mess. Automated dispensing systems and controlled assembly processes can help ensure consistent application.

Over time, some BTIMs may degrade or dry out, especially under harsh conditions. Regular inspection and potential replacement during maintenance can help sustain optimal thermal performance and prevent failures. In designs where reworkability is important, selecting a BTIM that can be removed and replaced without damaging components is also valuable.

Conclusion

Battery Thermal Interface Materials are a critical component of modern battery systems. They play an essential role in ensuring safe, efficient, and long-lasting performance by improving heat transfer between battery cells and their cooling systems. With the growing demand for electrification and energy storage, the importance of thermal management has never been greater. Whether in electric vehicles, stationary energy storage systems, or portable electronics, choosing the right BTIM helps manufacturers meet performance, safety, and durability requirements. By understanding the types of BTIMs available and their specific characteristics, engineers and designers can make informed decisions that lead to better thermal performance and more reliable battery-powered products.